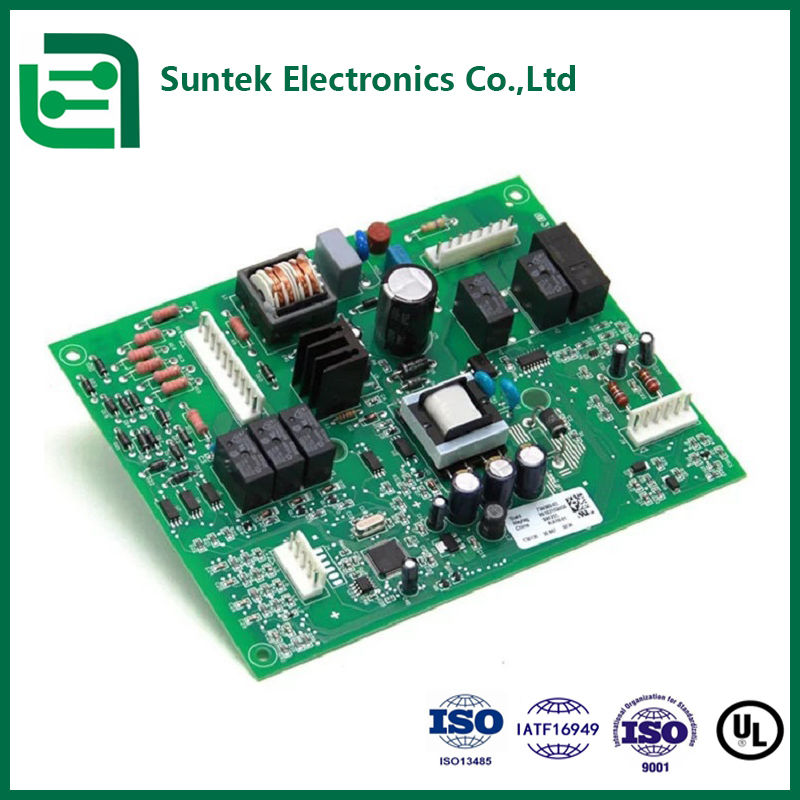

Customized Electronic SMT THT PCBA Assembly Suitable for Sensor X-ray Inspection

About Suntek Group:

Suntek Group is a contract supplier in EMS field with one-stop solution for FCB/FPC assembly,Cable assembly,and Box-build assembly.

Suntek Electronics Co., Ltd,as the major facility, located in Hunan Prov,China;

BLSuntek Electronics Co., Ltd,as the new facility,located in Kandal Prov,Cambodia.

With ISO9001:2015,ISO13485:2016,IATF 16949:2016 and UL E476377 certified,

We deliver qualified products with competitive price to clients all over the world.

Our Manufacturing Capability:

| Item |

Paramter |

| Board Type: |

Rigid PCB, Flexible PCB, metal core PCB,Rigid-Flex PCB |

| Board Shape: |

Rectangular, Circular and any irregular Shapes |

| Max Size: |

400mm * 1200mm |

| Min Package: |

0201 |

| Fine Pitch Parts: |

0.25mm |

| BGA Package: |

Acceptable |

| DIP Capacity: |

3 DIP lines and 1 AI assembly line |

| Parts Sourcing: |

All by Suntek or partical consigned by customer |

| Parts Package: |

Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk |

| Testing: |

Visual inspection, AOI, X-RAY,Functional Testing |

| Types of Solder: |

Lead or Lea-free (RoHS Compliant) assembly |

| Assembly Option: |

Surface mount (SMT), Through-hole (DIP), Mixed technology

(SMT & Thru-hole) |

| Stencils: |

Laser cut stainless steel stencils,step-down stencil |

| File Formats: |

Bill of Materials,PCB(Gerber Files),Pick-N-Place File (XYRS) |

| Quality Grade: |

IPC-A-610 Class 2/Class 3 |

Application:

* Automobiles,Machinery

* Electronical machine,Projector

* Advertising machine,Monitor,Home appliance

* Water Dispensers,Computer,Motherboard

* Military equipment,Air conditioner

* Communications-equipment,Power device,etc.

One-Stop EMS Service:

OEM service

| Layers |

1-32 Layers |

Copper weight |

0.5 oZ~10 oZ |

| Material |

FR4(Tg 135-Tg180) 94v0,Rogers,Aluminum |

Board cutting |

Shear,V-score,tab-routed |

| Board type |

Rigid, flexable, rigid-flexable |

Silk screen |

Single double-sided green LPI etc |

| Board shape |

Rectangular,round,slots,cutouts etc |

Design file format |

Gerber, CAD,.BRD |

| Board Thickness |

0.2~5.0mm,Flex 0.01~0.25 |

Bom format |

Excel,PDF |

Production:

PCB Assembly:

1)Our equipments include Desen Printing press,Samsung SMT, JT lead-free re-flow ovens, lead-free wave-soldering,BGA rework base,AI machine.

2) Surface mount,through-hole,BGA,QFP and QFN,0201 parts assembling.

3) AOl testing(X-ray for BGA package) for every piece board.

4)First article inspection before SMD process and First completed sample before DIP process.

5)Programming and function testing .

6)Conformal coating and Glue.

What Suntek Group Can Offer:

1. PCB and FPC bare board

2. PCB and FPC assembly

3. Components purchasing and materials customization

4. One-stop of turnkey box build assembly

5. Mixed technology mix assembly

6. Cable assembly and wire harness

7. Low/mid/high volume PCB assembly

8. BGA/QFN/DFN WITH X-ray insepction

9. IC programming/AOI/ICT/Functional test

FAQ:

Q1.What files for PCB quotation?

A:PCB files(gerber)

Q2.MOQ and what is the fastest delivery time?

A:There is no MOQ in Suntek. we are able to handle small as well as large volume production with flexibility. Samples need 3-5 working days,Mass production need 7-10 working days.

Q3.For PCB quotation, what files format do need?

A:Gerber, Protel 99SE, DXP, PADS 9.5, AUTOCAD,CAM350 are OK.

Q4.How to test PCB boards?

A:AOI, Fly probe testing, Text fixture testing, FQC etc for bare pcb.

We have advanced manufacturing equipments and technology,professional engineer team,purchasing team,quality team and management team to guarantee

the high quality products and on time delivery.Our products are widely used in industrial control,auto,telecommunications,medical equipment,consumer electronics and etc.

PCBA Equipments:

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!